What Are TIG Welding Rods?

TIG Rod is used in Tungsten Inert Gas welding, where a non-consumable Tungsten Electrode carries the arc, and TIG Wire is used to supply the filler metal. TIG Wire is a consumable to the process.

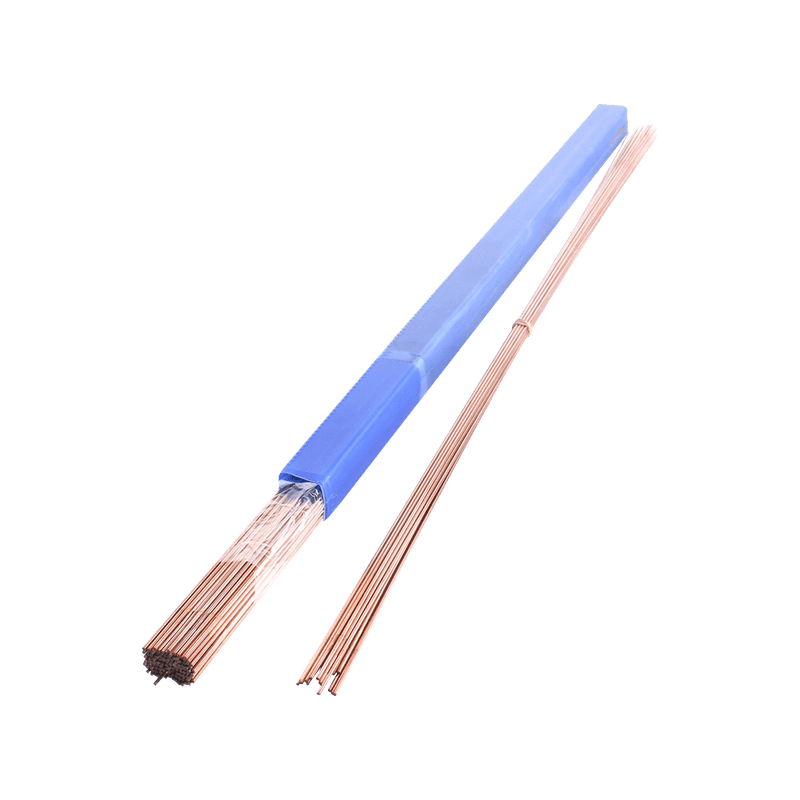

These are a pound (1lb) of 36" Mild Steel TIG Rods with 3/32" Diameter, AWS Classification

ER70S2 is a premium TIG wire for welding on all grades of mild and carbon steels, producing quality welds with minimal porosity. It is a triple deoxidized wire (Zirconium, Titanium, and Aluminum) making it an excellent choice for welding over rust and mill scale. This wire is available in 36-inch lengths and embossed on both ends for easy identification.

Features

- Excellent welding characteristics

- Precise control of wire chemistry

- Minimal contamination of wire surface during manufacturing process

- Consistent weld deposit chemistry and procedures from package to package improve quality and save time.

- Good bead wetting characteristics

- Great puddle control

- Clean welds, minimal "smut"

Applications

- Pipes

- Offshore drilling rigs

- Structural steel work

| Type | TIG Rod |

| Diameter | 3/32'' |

| Length | 36'' |

| AWS Classification | ER70S-2 |

| Standard | A5.18 |

| Tensile Strength | 83,000 psi |

What Are TIG Welding Rods?

TIG Rod is used in Tungsten Inert Gas welding, where a non-consumable Tungsten Electrode carries the arc, and TIG Wire is used to supply the filler metal. TIG Wire is a consumable to the process.

These are a pound (1lb) of 36" Mild Steel TIG Rods with 3/32" Diameter, AWS Classification

ER70S2 is a premium TIG wire for welding on all grades of mild and carbon steels, producing quality welds with minimal porosity. It is a triple deoxidized wire (Zirconium, Titanium, and Aluminum) making it an excellent choice for welding over rust and mill scale. This wire is available in 36-inch lengths and embossed on both ends for easy identification.

Features

- Excellent welding characteristics

- Precise control of wire chemistry

- Minimal contamination of wire surface during manufacturing process

- Consistent weld deposit chemistry and procedures from package to package improve quality and save time.

- Good bead wetting characteristics

- Great puddle control

- Clean welds, minimal "smut"

Applications

- Pipes

- Offshore drilling rigs

- Structural steel work

| Type | TIG Rod |

| Diameter | 3/32'' |

| Length | 36'' |

| AWS Classification | ER70S-2 |

| Standard | A5.18 |

| Tensile Strength | 83,000 psi |

RECENTLY VIEWED

- Choosing a selection results in a full page refresh.

- Press the space key then arrow keys to make a selection.